Discover what is the golden profit margin for machine factory manufacturing and learn how to achieve this key metric for success.

When it comes to running a manufacturing factory, making a profit is always on the minds of managers and owners.

You might be asking yourself, “What’s the secret profit margin that makes some factories more successful than others?”

Trust me, you’re not the only one who’s curious about this.

I’ve been there too, trying to find useful benchmarks and insights to help make better decisions that improve workplace productivity.

After years of research and chatting with industry leaders, plus learning from my own mistakes, I’ve figured out a solid way to understand and achieve this tricky goal.

So, let’s get into it.

Article Breakdown

What’s the Ideal Profit Margin?

Let’s start by addressing the numbers.

In machine manufacturing, profit margins can vary significantly based on scale, specialization, and market dynamics.

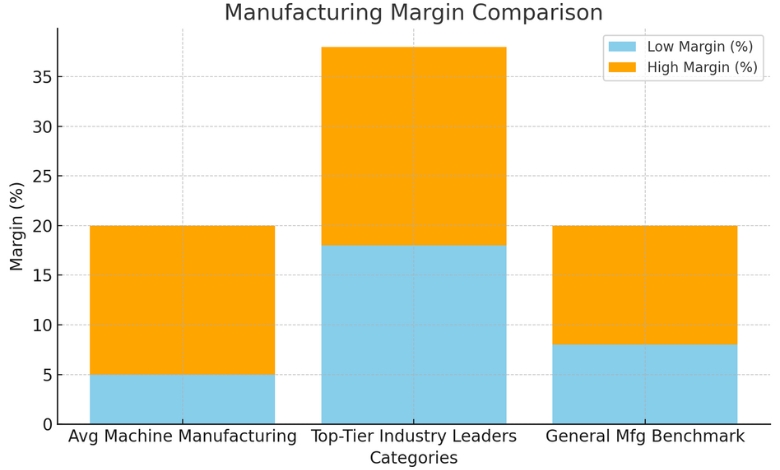

According to data from industry financial reports, the average net profit margin for machine manufacturing typically ranges from 5% to 15%, with top-performing companies reaching margins upwards of 20%.

Why such a range?

Well, the answer lies in a cocktail of factors—everything from supply chain efficiency to product innovation and market competition.

I remember my early days working alongside a mid-sized manufacturing firm where breaking even felt like a triumph.

But after digging deeper into market leaders’ data, it became clear: the companies consistently hitting that 15% to 20% range were doing things differently.

Where Machine Manufacturing Stands

To put it into perspective, general manufacturing industries like consumer goods and electronics often have profit margins ranging from 8% to 12%.

Machine manufacturing, especially in sectors producing specialized industrial equipment, can be more volatile but holds higher potential for significant profit margins.

This variability is why some factory owners scratch their heads and wonder, “Why is my margin just 5% when others are clocking in at 18%?”

It’s not always about scaling up; it’s often about smarter, leaner operations.

Take, for example, a case I studied involving two factories producing similar equipment.

One had a 9% margin, the other 19%.

The difference? A laser-focused approach to material sourcing and in-house innovations that cut down production costs.

What Drives Profit Margins?

The truth is, hitting a high-profit margin isn’t about luck or sheer market demand—it’s about strategy.

I spoke with a seasoned operations consultant, who shared a powerful insight:

“Profit is like a well-tuned engine. The parts—cost control, efficiency, and value addition—all need to work in harmony.”

Factors Affecting Profit Margins:

| Impact on Margins | Solution Strategy | |

| Raw Material Costs | High variability | Hedge contracts, bulk buying |

| Labor Costs | Direct impact | Training, efficiency incentives |

| Production Downtime | Reduces output | Preventative maintenance schedules |

- Raw Material Costs: In machine manufacturing, the price of materials can eat into profit margins faster than you’d think. I recall a particularly tough quarter when raw steel prices soared by 20%. For those not hedging against such fluctuations, it was a nightmare.

- Labor Efficiency: Skilled labor is both a blessing and a balancing act. Higher wages can hurt short-term margins but investing in training and streamlined processes pays off. Think of it as fine-tuning a race car: initial tweaks can seem costly but result in peak performance.

- Technology and Automation: Factories embracing automation often find their profit margins leap by a few points. A friend of mine, who manages a parts manufacturing line, saw a 12% boost in profit margin after integrating an automated welding system. It wasn’t cheap, but it paid for itself in under two years.

Strategies for Optimizing Profit Margins

“Alright, so what’s next?” you might be thinking.

Here’s where the rubber meets the road.

You’ve got the numbers and the underlying factors; now let’s look at actionable strategies to get your profit margins climbing.

1. Lean Manufacturing Principles

Adopting lean manufacturing principles isn’t just a buzzword—it’s a proven path to profitability.

Your factory is like a water hose; waste is the kink that stops the flow. Lean methods are about finding and straightening those kinks.

- Example Strategy: Implement just-in-time (JIT) inventory management to reduce storage costs and waste.

- Real-World Result: A mid-sized factory that transitioned to JIT saw a 10% reduction in overhead, which directly bumped their profit margin by 2%.

2. Invest in Training and Workforce Development

A well-trained workforce isn’t just an asset; it’s a competitive edge.

Investing in skill development leads to fewer production errors, higher output quality, and less downtime.

My own experience with a training overhaul in a production unit led to a 15% decrease in defective products, which translated to significant cost savings.

3. Diversify Your Product Line

Relying solely on one type of machinery or market can expose you to downturns.

Diversification allows you to tap into different revenue streams.

One manufacturing firm I studied expanded from making standard industrial presses to customizable, tech-enhanced models.

Their profit margin jumped from 10% to nearly 17% over a two-year period.

Key Takeaways

At this point, I hope you feel armed with valuable insights. But just to make sure everything is crystal clear, here’s a quick recap:

- Know Your Baseline: The average machine manufacturing profit margin sits between 5% and 15%, with the golden zone being 15% or higher.

- Optimize Your Operations: Lean practices, smart technology investments, and efficient workforce management are essential.

- Think Long-Term: Short-term sacrifices, like investing in training and automation, can lead to long-term gains.

- Be Adaptable: Market changes, raw material costs, and labor dynamics fluctuate. Stay flexible to stay profitable.

Additional Resources:

- Flintfox: Increase Profit Margin in Manufacturing: Discover strategies to boost your manufacturing profit margins effectively.

- Craftybase: 6 Ways to Increase Your Profit Margin: Explore six practical tactics to enhance your profit margin in manufacturing.

- USCCG: How Revenue Technology Brings Significant Value for Manufacturing Businesses: Learn how revenue technology can drive profitability in manufacturing companies.

- Xait: How to Increase Profit Margins in Manufacturing: Gain insights on effective methods to improve profit margins in the manufacturing sector.