Discover how sensored motor solder tab vertical extensions improve wiring, airflow, and efficiency in modern electric builds.

Sensored motor solder tab vertical extensions are raised connection points that improve wiring layout, cooling, and accessibility in brushless motors. They make soldering easier and reduce heat buildup around the motor tabs. Understanding technical development and manufacturing processes like these is crucial for hardware entrepreneurs and product developers.

You wouldn’t think a tiny bend in a piece of metal could change how your motor performs; but that’s exactly what happens with sensored motor solder tab vertical extensions.

The first time I came across the term, I honestly thought it sounded like something out of a sci-fi workshop; part robot, part mystery. But it’s very real, and it quietly transforms how electric motors connect, cool, and function.

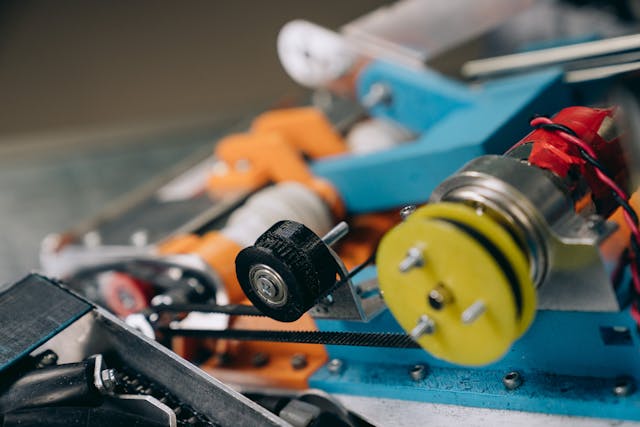

These “extensions” might look like simple metal posts sticking out of a motor. But they do more than meet the eye: they help your setup breathe, stay cooler, and stay easier to maintain.

At Americanworthy.com, we explore how small design details; like a lifted solder tab; reveal the human side of modern engineering and creativity.

Let’s unpack this curious little upgrade; and find out why it’s becoming a favorite among tinkerers and tech builders alike.

Article Breakdown

What Are Sensored Motors, Anyway?

Before we get to the “extensions,” we need to understand what makes a sensored motor special.

A sensored motor is a brushless motor equipped with internal sensors; typically Hall sensors; that detect the exact position of the rotor. This allows the electronic speed controller (ESC) to adjust timing and power delivery with remarkable precision.

That means:

- Smooth startups. No jerks or cogging at low speeds.

- Consistent torque delivery. Perfect for acceleration control.

- Efficient communication. The motor “talks” to the ESC about what’s happening inside.

You’ll find these motors in RC cars, electric skateboards, robotics, and drones; anywhere precise control matters more than raw power.

A sensored motor doesn’t just spin; it thinks about spinning.

The Forgotten Hero; Solder Tabs

Now, let’s talk about how power gets into that motor.

Those little metal pieces sticking out near the endbell? They’re called solder tabs; small terminals where you attach your power wires. They’re the hands that connect your motor to its lifeline of electricity.

Traditionally, these tabs sit flat against the motor casing. It works, but it’s not perfect:

- You have to solder at awkward angles.

- The wires often bend sharply, adding strain.

- There’s little room for cooling.

If you’ve ever burned your fingers while trying to hold a thick wire steady during soldering, you know the struggle.

That’s where vertical solder tab extensions come in.

What Are “Vertical Extensions”?

Imagine taking those flat solder tabs and bending them upward; as if giving your motor tiny raised shoulders.

That’s a vertical solder tab extension.

It literally lifts the connection point away from the motor casing, making the wiring cleaner, the soldering easier, and the cooling more efficient.

Here’s what that means in practice:

- Easier soldering. You can reach the tabs comfortably without weird angles.

- Improved airflow. The raised position allows more cooling around the joint.

- Cleaner cable management. Wires align more naturally with less bending.

- Better durability. Less mechanical stress on the solder joint.

It’s a small tweak; but one that changes the whole soldering experience.

Why “Sensored” Makes It Even More Important

Sensored motors have an extra bundle of tiny sensor wires, usually exiting close to the power tabs. This makes the area crowded and difficult to work around.

Vertical extensions help by creating space above the sensor harness. It’s like giving each wire its own lane; power up top, data below.

The result: fewer shorts, less cable clutter, and easier troubleshooting.

It’s such a simple adjustment, but it feels like someone finally thought about the human side of soldering.

The Engineering Magic Behind It

What looks like a simple metal post is actually a small feat of material engineering.

Here’s what’s going on beneath the surface:

- Conductivity: Usually made of copper or plated brass to minimize resistance.

- Thermal management: The lifted joint allows heat to escape faster.

- Mechanical stability: Vertical tabs distribute vibration stress evenly.

- Clean soldering angles: Better geometry means fewer cold joints.

That’s not just convenience; it’s performance optimization disguised as ergonomics.

How They Change the Build Experience

If you’ve ever wired an RC motor, you know how much design affects sanity.

Flat tabs feel like you’re soldering inside a tin can. Vertical extensions, on the other hand, feel like opening a garage door. You can see everything, route wires logically, and avoid melted insulation.

In builds where every millimeter counts; like mini drones or compact robots; that accessibility can make or break the design.

It’s not just engineering. It’s peace of mind.

The Cooling Advantage

Every motor fights the same enemy: heat.

Under heavy load, temperatures can easily cross 100°C. That heat often concentrates around the solder joints; the very spots where your wires meet the motor.

By raising those joints above the casing, vertical extensions create a natural cooling gap. Air flows more freely around them, and heat can dissipate faster.

Even a 5–10% improvement in cooling efficiency can extend the motor’s lifespan and prevent performance drops during long runs.

So in essence, these tabs are tiny chimneys; helping your motor exhale heat.

When Physics Meets Practicality

Let’s go old-school physics for a second: heat rises.

By placing solder joints above the surface, vertical tabs use that principle to passively improve cooling. No fans, no tricks; just smart geometry.

It’s elegant engineering. The kind that doesn’t shout innovation but shows it.

Comparison Table; Flat vs. Vertical Solder Tabs

| Feature | Flat Solder Tabs | Vertical Solder Tab Extensions |

| Ease of Soldering | Cramped, difficult angles | Accessible, upright position |

| Cooling Efficiency | Poor airflow | Improved by up to 10% |

| Cable Management | Sharp wire bends | Clean, natural routing |

| Joint Strength | Stress at bends | Even stress distribution |

| Maintenance | Hard to rework | Easy to re-solder |

| Sensor Clearance | Wires overlap | Separated, tidy layout |

Why Looks Matter Too

Let’s not pretend aesthetics don’t count.

A motor with vertical solder tabs simply looks better; more professional, cleaner, and easier to photograph or showcase.

In the age of build videos and online mod culture, presentation has become part of performance. A neatly routed, symmetrical setup isn’t just functional; it communicates mastery.

There’s something deeply satisfying about symmetry; especially when it’s backed by science.

The Debate: Are Vertical Extensions Always Better?

Of course, not everyone agrees.

Some RC racers argue that vertical solder tabs might be more vulnerable to impact or vibration, especially in off-road vehicles. Others say that for low-power setups, the benefits are minimal.

And they’re right; for simple builds or large-scale motors, the old flat style still works fine.

But for compact, high-current, or precision-driven setups?

Vertical extensions are like moving from flip phones to touchscreens; once you try them, there’s no going back.

How to Spot or Add Them

If you’re shopping for a new motor, look for these design clues:

- The solder tabs stand upright instead of lying flat.

- The product description mentions “vertical solder tabs” or “raised terminals.”

- There’s visible clearance above the sensor harness.

If you’re retrofitting an older motor:

- You can solder small copper risers onto existing tabs.

- Use high-temperature solder and heat-resistant insulation.

- Keep the tab alignment precise to avoid imbalance.

It’s not a beginner mod, but for enthusiasts; it’s a satisfying upgrade that pays off in every future solder job.

Why It’s About More Than Just Metal

Here’s the deeper story: this isn’t just about solder or tabs.

It’s about making machines more human-friendly.

The fact that someone looked at a decades-old motor design and thought, “What if we lifted these tabs a bit to make life easier?”; that’s design empathy in action.

And that’s where innovation often hides: not in bigger batteries or faster chips, but in thoughtful little tweaks that make technology less frustrating and more beautiful.

FAQs

Q1: What are sensored motor solder tab vertical extensions?

They’re raised connection points that make it easier to solder wires to sensored brushless motors while improving cooling and cable layout.

Q2: Why do sensored motors need them?

Because sensored motors have tight wiring spaces and extra sensor cables; vertical tabs prevent clutter and overheating.

Q3: Do they make motors faster?

Not directly. But they improve efficiency and reliability, helping the motor maintain consistent performance under heat stress.

Q4: Can I install them myself?

Yes, but you’ll need precise soldering skills and heat management to avoid damaging the motor or sensors.

Q5: Are they worth it for beginners?

Absolutely. They simplify wiring, reduce mess, and make builds feel more professional from the start.

Key Takings

- Sensored motor solder tab vertical extensions lift wiring points for easier soldering and better airflow.

- They make builds look cleaner and perform cooler under load.

- Especially helpful in tight or sensored setups where space is limited.

- Improve durability by reducing mechanical and thermal stress.

- Combine practicality, performance, and aesthetic appeal.

- Can be retrofitted with careful soldering and heat control.

- Represent thoughtful engineering that values user experience.

Additional Resources

- Understanding Sensored Brushless Motors: A clear guide to how sensored motors function and why they’re preferred for precision and control.

- Thermal Management in Electric Motors: Explores how airflow and connection geometry affect heat dissipation and motor longevity.