Higher WIP levels can cost your business on many grounds. So what should you do? Understanding & controlling WIP is the answer.

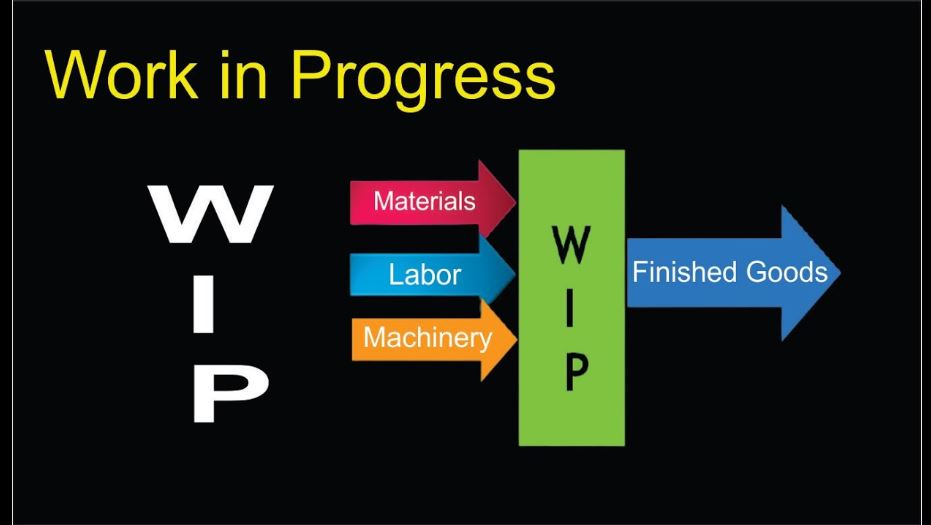

Work in Progress is central to production systems across industries. It’s used for partially completed goods, components, or projects that have already started their journey along the production lines but haven’t yet reached completion.

Better to say, WIP is a transitional state with no raw materials and no finished products ready for sale and delivery.

WIP manufacturing, in particular, encompasses all materials, labor, and overhead costs invested in the products that are still moving through the production cycle.

Therefore, understanding WIP is crucial. Why? Because it involves capital that has been deployed but hasn’t generated returns yet. It’s your money in motion with ROI awaited.

Article Breakdown

The Fundamental Nature of WIP Manufacturing

WIP represents a state of transformation. In general terms, it resembles the transformational stage of a butterfly’s life cycle — the cocoon stage, when it’s neither the caterpillar nor the butterfly, but something in between that requires time, energy, resources, and effort to transform.

In business, this transformation comes with both costs and strategic implications.

| Capital CommitmentEvery item in WIP represents invested capital, which cannot be used elsewhere. | Time InvestmentWIP items occupy production capacity for varying periods |

| Value AdditionEach stage in the manufacturing or production process adds value to WIP items. | Risk ExposureUntil completed, WIP items have this risk of rework, damage, or obsolescence. |

For managers and business owners, the goal is to optimize WIP. They must focus on maintaining just enough to keep production flowing smoothly without tying up excessive resources.

WIP Across Manufacturing

WIP is quite visible in traditional manufacturing. Consider the following examples to understand this better:

Automotive Production

A vehicle, before completion, might pass through 50+ workstations. At any given time, hundreds or thousands of cars exist in various stages. From being welded, engines being installed, electronics being tested, or interiors being assembled, each represents WIP with different value levels.

Electronics Manufacturing

A smartphone’s manufacturing journey involves circuit board assembly, component installation, software loading, and quality testing.

A factory producing 10,000 phones daily might have 30,000+ units in various WIP stages.

Food Processing

Even in continuous production setups like beverage bottling, WIP exists. Formation of bottles, filling, capping, labeling, and packaging represent various WIP stages.

The only difference is – they move much faster than in discrete manufacturing.

The Financial Significance of WIP

WIP on the Balance Sheet

WIP occupies an important position on a company’s balance sheet, sitting between raw materials and finished goods inventories.

It is calculated as:

WIP Inventory = Beginning WIP + Manufacturing WIP Cost Added – Cost of Goods Manufactured

Where:

- Beginning WIP represents the previous period’s ending WIP value

- Manufacturing costs include raw materials moved into production, direct labor, and allocated overhead

- Costs of Goods Manufactured refers to items that have completed production and moved to finished goods

For manufacturers, WIP can represent 15-30% of total inventory value, making it a significant asset that impacts multiple financial metrics:

WIP represents a significant asset for manufacturers as it can account for 15-30% of the total inventory.

| Working CapitalHigher WIP levels increase working capital requirements | Cash Conversion CycleLonger production times extend the cash conversion cycle |

| Return on Assets (ROA)Excessive WIP can depress ROA by increasing the asset base without corresponding revenue. | Inventory TurnoverHigh WIP levels generally reduce inventory turnover ratios |

Common WIP Manufacturing Problems

Manufacturing units often face the following challenges:

- Excessive Inventory: Making large batches creates excess WIP that sits idle

- Unbalanced Workstations: Sometimes various stations work at different paces – one works faster than others – WIP piles up

- Poor Visibility: unclear, unsure, and not knowing where items exactly are in the production line

- Quality Issues: Finding defects way later in production wastes all the previous work and efforts

- Equipment Breakdowns: Machine failures often create WIP bottlenecks

Practical Ways to Improve WIP in Manufacturing

WIP in manufacturing can be improved on many grounds with various strategies at hand. Let’s look at these solutions:

Basic Shop Floor Techniques

On the manufacturing floor, WIP can be improved by the following:

| Visual Management BoardsSimple boards showing WIP levels at each station | Daily Production MeetingsBrief team meetings to address WIP issues bring a prominent change. |

| Red/ Yellow/ Green SignalsColor-coded systems to identify and exhibit when WIP is too high | Standard Work InstructionsClear steps and instructions reduce mistakes and rework |

| 5S OrganizationKeeping workstations clean and organized can dramatically improve the workflow. | |

Simple Technology Solutions

- Barcode Scanning: Tracking items as they move through production can be of great help

- Basic Production Software: Programs that monitor WIP levels must be installed

- Digital Dashboards: Screens showing current WIP status can ensure a prominent improvement.

- Automated Alerts: Notifications when WIP exceeds targets

- Simple reporting: Daily reports to spot and show where WIP is building up

Benefits of WIP for Manufacturers

WIP must be kept low and smoothly flowing. Why? Because it gives the manufacturing companies:

- Faster delivery when products are completed

- Less room is needed to store partially finished goods, so no extra space or warehousing is required.

- Lower costs and less money tied up in partially completed products

- Fewer quality problems as issues can be spotted earlier when there’s less WIP

- Better work morale and less frustration among team members

Getting Started with WIP Improvement

Manufacturers can begin with these basic steps:

| Count Your Current WIP | Get to know how many items are in your manufacturing process. |

| Map Your Flow | Create a simple diagram of how products move through your manufacturing unit |

| Find Bottlenecks | Identify areas where WIP tends to pile up |

| Set WIP Limits | Establish maximum amounts of WIP allowed at each step |

| Measure Daily | Track WIP levels and production output each day, every day. |

| Make Small Changes | Adjust one process at a time and observe the results. |

Key Takings

- WIP in manufacturing is a key indicator of how smoothly your production flows.

- Manufacturers can build products faster with less space occupied, less capital tied up, and fewer problems only if they understand and control WIP.

- As a business, mastering WIP management can help you improve your manufacturing performance. So, go ahead and get the edge over your competitors.